Observation, Analysis, and Measurement of High-Performance Multilayer Films

With the film and sheet industry pushing towards increased functionality and multi-layered films, it is experiencing an increased need for observation, inspection, and analysis.

This section introduces industry trends, common defects and their causes, and the latest examples of solving conventional problems with the new 4K digital microscope.

- Increasing Needs in High-Performance Films

- Manufacturing Multilayer Films

- Higher Performance and Quality Demand in Films

- Latest Examples of Observation, Analysis, and Measurement of Films and Sheets

- Film thickness measurement with multilayer film cross-section

- Observation and 3D shape analysis of pinholes

- Observation of foreign particles and fish eyes

- Observation of foreign particles after removing ring reflection from a film surface

- Observation and evaluation of scratches on a film surface

- Texture observation and 3D measurement of a film surface

- High-resolution images of tears in chemical packaging films

- A New Cornerstone for High-performance Film and Sheet Evaluation

Increasing Needs in High-Performance Films

Plastic (resin) films and sheets with higher performance, thanks to lamination and other techniques, are seeing increased demand due to the needs of the market.

For example, against the backdrop of “individualised meals” in the food industry, the demand is increasing for food packaging for a larger variety of food in smaller portions targeting single-person households. Packaging needs are also increasing for refillable products such as shampoo, body wash, detergent, and other commodities where the bottle is reused. Functional films and sheets are also essential for the surface protection of wafers and the manufacturing of ceramic capacitors in the semiconductor and electronics industries. Other applications include laminated cell housing for (pouch) lithium-ion batteries.

Manufacturing Multilayer Films

Most high-performance films consist of different types of plastic stacked on various materials, such as aluminium, and laminated with a coating agent. Common lamination processes used for the manufacturing of multilayer films are as follows:

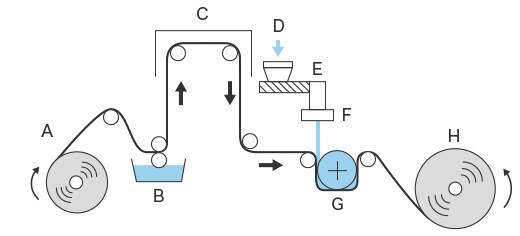

- Extrusion Laminating

- Extrusion laminating is a process that utilises extrusion moulding, a type of injection moulding technique. The substrate is precoated with an adhesion additive (anchor coat), and the material is melted by heat and extruded into an even, flat sheet through a die with a slit (T-die) as it is applied over the substrate. The material is compressed and solidified by the cooling roller to achieve bonding with the substrate. High-performance films can be created by “sandwich lamination” where three layers are bonded, “tandem lamination” where five layers are bonded, and multilayering by co-extrusion of multiple different material using a T-die.

- A. Substrate

- B. Adhesion additive coating (anchor coat)

- C. Drying zone

- D. Material

- E. Extruder

- F. T-die

- G. Cooling (cooling roller)

- H. Winding

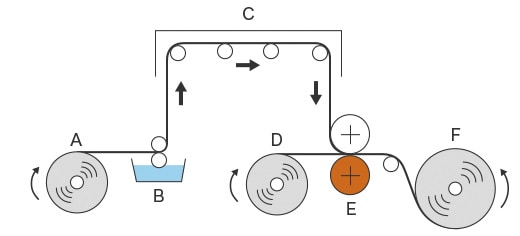

- Dry Lamination

- After adhesive or glue is applied to the first substrate, it is bonded with the second substrate, which is made of a different material. Using adhesive tape or other adhesion methods used in manufacturing, the substrates are bonded through a drying or heating process according to the properties of the adhesive or glue. Then, substrates are rolled up.

- A. First substrate

- B. Adhesive coating

- C. Drying zone

- D. Second substrate

- E. Heating (steel roll)

- F. Winding machine

Higher Performance and Quality Demand in Films

Multilayer films are required to have both high quality and functionality, including heat resistance, cold resistance, shock resistance, chemical resistance, aroma retaining properties, or damp proofing properties. Therefore, reliability testing and evaluation are well-practiced. The competition in research and development along with manufacturing of higher added value films is becoming increasingly fierce. In addition to surface strength, seal performance, and barrier properties, there is the continuous pursuit for enhancements such as microwave compatibility, “easy-open” qualities, and the ability to heat-seal for higher productivity.

Risk of undetected defects and defective products

Multilayer films are commonly used for food and drugs, which demand a high level of safety and reliability along with functionality. Particular care is required to detect and prevent defects and non-conformities.

Typical defects in films and sheets include “fish eyes,” which are bumps on the surface that show up as a result of uneven film thickness. This issue can be traced back to unmelted material, and “pinholes,” which are caused by puncturing, friction, or bending fatigue. Other microscopic defects such as scratches, tears, and defects caused by foreign particles can also result in unsatisfactory packaging, which can further lead to impairing the quality of the content of the package. Poor package quality can lead to complaints from customers.

Importance of observation and analysis

To ensure the quality of such high-performance films and sheets, greater importance is placed on evaluation based on detailed microscopic observations and analyses in the areas of R&D and manufacturing. At the same time, high-accuracy analyses and measurements, as well as shorter turnaround time to produce accurate evaluations, are in demand to accommodate high-performance films with strict film thickness accuracy requirements and rapid product cycles.

Latest Examples of Observation, Analysis, and Measurement of Films and Sheets

Conventional microscopes have the following problems in terms of observing, analysing, or measuring films and sheets:

- When measuring the film thickness of a cross-section sample, the observation surface is uneven, preventing correct observation and measurement.

- Shapes of pinholes cannot be observed, which means that the direction from which the puncture occurred cannot be analysed.

- Magnified observation of microscopic scratches, foreign particles, and fish eyes cannot be performed due to insufficient resolution.

- With glossy films, light reflecting off the film hampers observation.

- With uneven surfaces, the image only focuses on a part of the surface.

KEYENCE’s VHX Series high-definition 4K Digital Microscope offers clear 4K images and a proprietary system that, with our large depth of field and high resolution, allows high-magnification observation and high-accuracy 2D and 3D measurements. It solves conventional problems while also contributing to more accurate evaluations that can be done both quickly and easily.

This section introduces the latest examples of film observation, analysis, and measurement using the VHX Series.

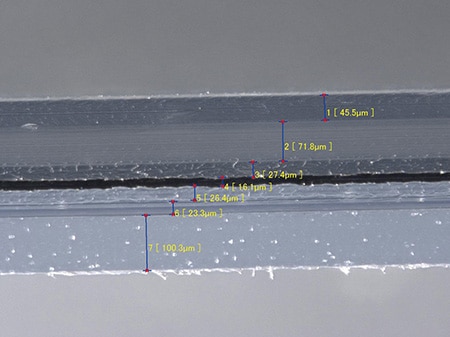

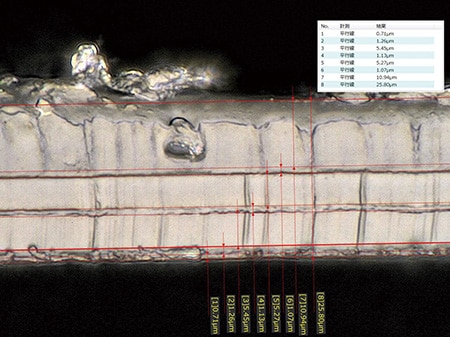

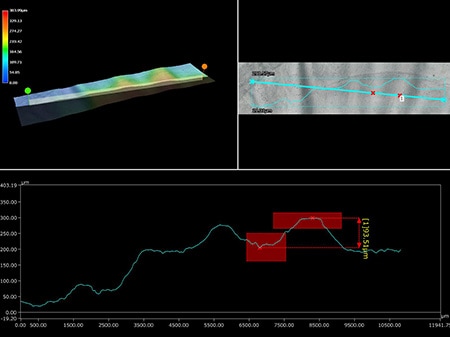

Film thickness measurement with multilayer film cross-section

When a conventional microscope is used to measure the thickness of each layer in a multilayer film using a cross-section sample, only a part of the sample can be brought into focus at a time unless the observation surface is completely uniform. Additionally, such measurements usually require the user to load the image into a separate software, increasing the time required.

The VHX Series 4K Digital Microscope has developed a depth of field that is approximately 20 times deeper than that of conventional, general microscopes. This allows users to capture high-resolution images of thin films at high magnifications.

In the event that the surface is uneven, the real-time depth composition function can be used to create a fully focused 3D image.

High-accuracy 2D measurement is also available by simply selecting a tool and specifying the part you want to measure on the high-magnification image. Furthermore, a report function that automatically inputs the magnified image and measured values into a template of your choice is provided to quickly complete a series of tasks on just a single machine.

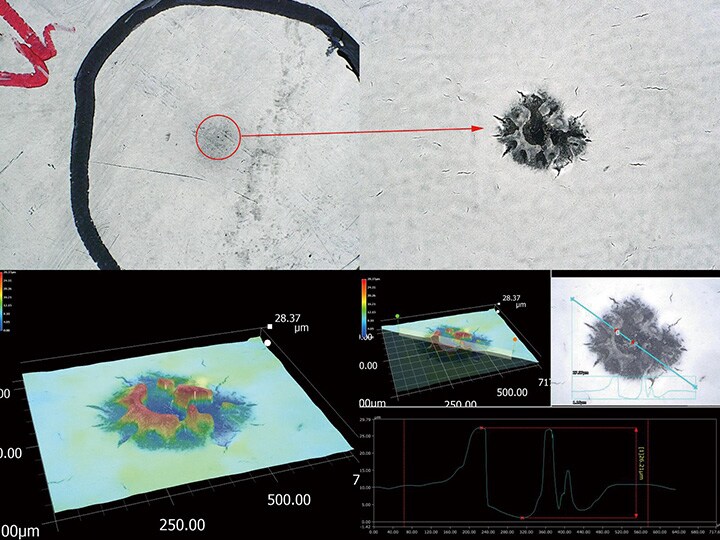

Observation and 3D shape analysis of pinholes

The VHX Series 4K Digital Microscope can use high-resolution, high-magnification images for clear observation of pinholes, which was not possible with conventional microscopes.

High-accuracy 3D shape measurement is also possible by using the high-resolution magnified images. Additionally, any cross-section can be used for profile measurement, enabling accurate analysis and swift quantitative evaluation from detailed pinhole shape data.

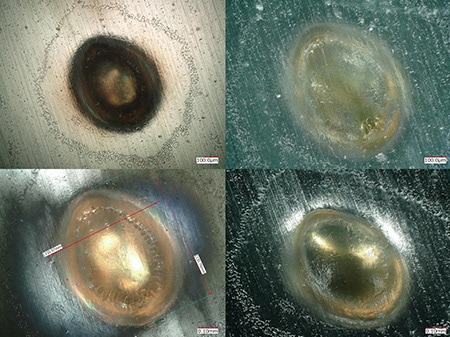

Observation of foreign particles and fish eyes

The VHX Series 4K Digital Microscope can use diverse functions to clearly capture microscopic flaws, thereby enabling accurate and fast observation, analysis, and evaluation.

The multi-lighting function obtains multiple images with omnidirectional lighting at the push of a button. The user can then select the image that is optimal for analysis, greatly reducing time spent on adjusting lighting settings. After the image is captured, the direction of the lighting can be further manipulated for detailed inspection.

This works even with glossy films where the glare removal function removes light reflections to help accurately capture the details of the defect. Clear high-resolution images can be used for high-magnification observations that support up to 6000x. These observations enable you to study the details of microscopic foreign particles.

using the multi-lighting function

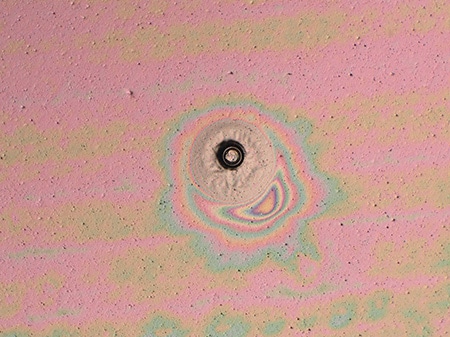

Observation of foreign particles after removing ring reflection from a film surface

Previously, foreign particles trapped in a film with a glossy surface cause a mound in the film that reflects light in a ring-like pattern, thereby rendering accurate observation and analysis of the shape of the inclusion difficult.

The ring-reflection removal function of the VHX Series 4K Digital Microscope supports accurate observations of the shape of foreign particles trapped in a film.

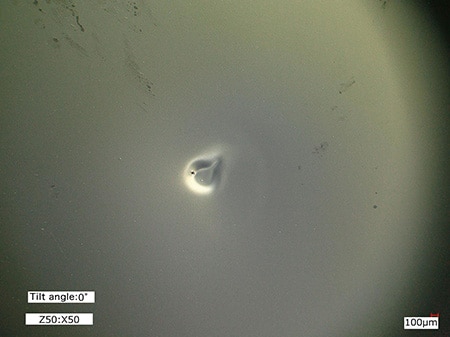

Observation and evaluation of scratches on a film surface

Conventional microscopes lack the resolution necessary to observe and evaluate scratches on the surface of transparent films.

The VHX Series 4K Digital Microscope can use high-definition 4K images created by the high-resolution lens and 4K CMOS for an easy and accurate observation and evaluation of the film surface.

Texture observation and 3D measurement of a film surface

Due to their insufficient depth of field, conventional microscopes cannot readily focus on textured surfaces of films in high-magnification observations.

With the VHX Series 4K Digital Microscope, fine details of texture on the film surface can be clearly observed using different lighting settings.

3D shape and profile measurements are also possible directly from the magnified image, thereby enabling quantitative evaluation of the surface conditions based on data.

High-resolution images of tears in chemical packaging films

Tears and other defects in chemical packaging films can lead to leakage and deterioration of the content. The cause must be identified through close inspection from a quality assurance perspective.

However, conventional microscopes lack the resolution for capturing the details of tiny tears in the film.

The VHX Series 4K Digital Microscope is equipped with a high-performance lighting and observation system as well as a high-resolution lens and a 4K CMOS that together contribute to a deep depth of field. These aspects enable the clear expression of fine tears even during high-magnification observation.

These features enable easy and quick observation of the details that reveal whether the tear is in the machine direction (MD) or the transverse direction (TD) and whether the tear was inflicted from the inside or outside. Such observation contributes to the quick identification of the cause and to implementation of process improvements.

A New Cornerstone for High-Performance Film and Sheet Evaluation

The VHX Series high-definition 4K Digital Microscope not only resolves the issues in the conventional observation, analysis, measurement, and evaluation of films and sheets, but it also enables detailed observation of microscopic defects that were previously undetectable.

Today, film and sheet products are seeing an intensified race toward higher functionality. The VHX Series can be your new partner that supports the R&D and manufacturing of any film or sheet by offering sophisticated observation, analysis, and measurement, which are essential to ensure the reliability of such products.

In addition to the functions introduced here, the VHX Series is equipped with many more useful functions inspired by the feedback and input from actual R&D and manufacturing sites. For additional product info or inquiries, click the buttons below.