Observation and Measurement of PET Plastic Bottles Using Digital Microscopes

Most plastic bottles we use in everyday life are made from polyethylene terephthalate (PET), which is a type of resin made from petroleum. This material has been commonly used for beverage containers because it complies with the Food Sanitation Act and is safe, light, and highly recyclable. This section introduces the characteristics and manufacturing method of plastic bottles made from PET along with examples of how they are observed and measured using digital microscopes.

- Characteristics of PET Bottles

- PET Bottle Manufacturing Method

- PET Bottle Cap and Label Materials

- Petaloid Shape

- PET Bottle Observation and Measurement Examples Using Digital Microscopes

Characteristics of PET Bottles

Thanks to the following characteristics, PET bottles are widely used for beverage containers in everyday life.

- PET bottles are safe and sanitary, complying with the Food Sanitation Act.

- PET bottles are lighter and harder to break than glass bottles.

- PET bottles are recyclable, so they are eco-friendly.

- PET bottles change to carbon dioxide and water when burned, emitting no harmful substances.

- PET bottles can be capped repeatedly.

- The contents can be seen because PET bottles are transparent.

- PET bottles are easy to process and there are a wide range of sizes.

PET Bottle Manufacturing Method

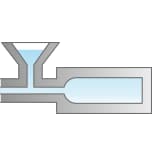

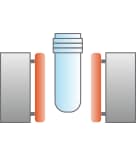

Typical PET bottles are manufactured with the biaxial stretch blow moulding method as shown below.

Materials of PET Bottle Caps and Labels

Bottles are made from PET, but their caps are made from polypropylene (PP) and their labels are made from polystyrene (PS). PET, PP, and PS are selected for the following reasons.

- PP caps easily contact tightly when closed because PP is softer than PET.

- PP is easy to process such as for threading and antiskid forming.

- PET labels are too hard to wrap around bottles.

Some recent PET bottles have no labels.

While PET sinks in water, PP floats. Consequently, these properties prevent them from being mixed with each other when recycled.

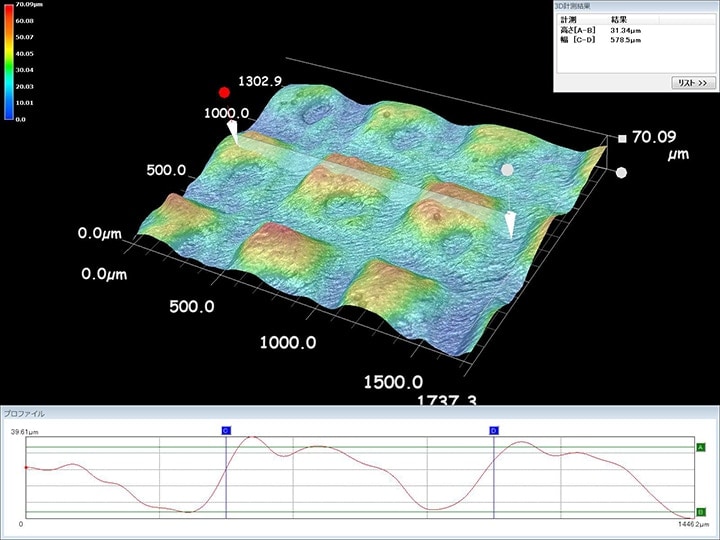

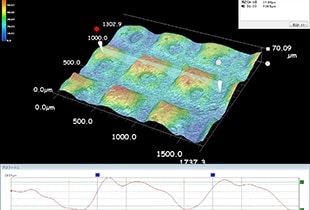

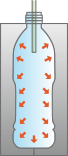

Petaloid Shape

PET bottles for carbonated drinks, which are called pressure resistant bottles, always have circular cross-sections with thick walls. Additionally, there are five hemispherical projections on the bottoms. These projections seem like petals, which is considered the ideal shape to withstand gas pressure.

PET Bottle Observation and Measurement Examples Using Digital Microscopes

These are the latest examples of observation and measurement of PET bottles using KEYENCE’s VHX Series 4K Digital Microscope.

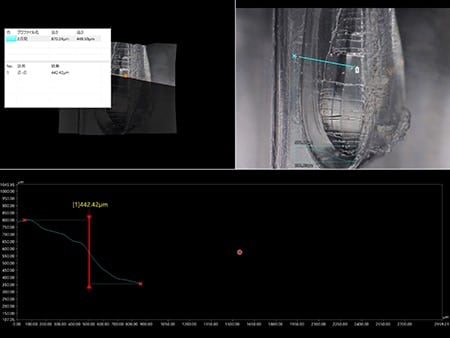

Image focused on the bottle head

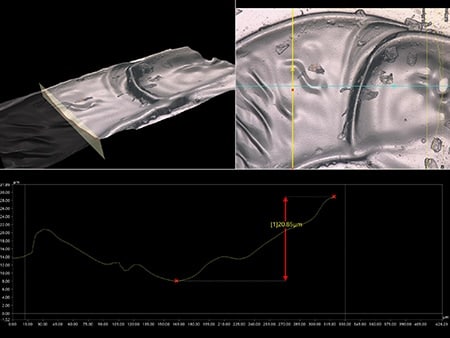

Image focused on the bottle bottom

A long working distance and a large depth of field allow for container observation without cutting.