Other Industries

Observation and Measurement of Food Containers and Packaging Using Digital Microscopes

As the scale of supermarkets and other retail stores expands, and convenience stores increases, the variety of food containers and packaging is growing more diverse. This section provides an overview of food containers and packaging and introduces examples of their observation using a digital microscope.

- Purposes of Food Containers and Packaging

- Typical Food Container Materials and Features

- Typical Food Packaging Types, Features, and Applications

- Observation and Measurement Examples of Food Containers and Packaging Using a Digital Microscope

Purposes of Food Containers and Packaging

Food containers and packaging are used for the following purposes.

- Prevention of spoiling

- Sealing food in an airtight container prevents spoiling by ensuring that the food is not exposed to oxygen.

- Ease of distribution

- The improved thermal insulation and strength provided by food containers and packaging make it easier to distribute food by preventing deterioration and damage.

- Health and safety

- Helps prevent contamination by foreign particles, ensuring health and safety even if consumers touch the food directly with their hands.

- Ease of use

- Food containers and packaging are shaped to make their contents easy to remove while also having improved stability that makes it difficult for their contents to spill out.

- Environmental consideration

- Food container and packaging materials are recyclable.

- Information transmission

- Display information on the food they contain, transmitting this information to consumers. This displayed information improves the effectiveness of advertising for sales promotion.

Typical Food Container Materials and Features

Typical food container materials, features, and applications are as follows.

- Polystyrene

- Used in room-temperature applications, this material has excellent stiffness and good formability.

- Heat resistant temperature: 80°C

- Foamed polystyrene

- Used in room-temperature applications, these containers have excellent stiffness, good formability, moisture-retaining properties, and thermal insulation properties.

- Heat resistant temperature: 80°C

- Polypropylene

- This material is resistant to oil and heat and can be used in microwaves.

- Heat resistant temperature: 110°C

- Foamed polypropylene

- The foaming process provides this material with thermal insulation properties, allowing consumers to hold hot food contained in this material in their hands.

- Heat resistant temperature: 130°C

- Polypropylene with filler

- This material is resistant to oil and heat and can be used in microwaves.

- Heat resistant temperature: 130°C

- Amorphous polyethylene terephthalate

- Although this material is weak to heat, it is transparent and resistant to oil and is used in applications such as salad and side dish containers.

- Heat resistant temperature: 60°C

- Polylactic acid

- A biodegradable plastic made from plants, this eco-friendly material helps reduce CO2 emissions. After they are used, products made from this material are broken down into water and carbon dioxide by microorganisms. This material has excellent transparency and is used in salad and cut fruit containers.

- Heat resistant temperature: 50°C

Typical Food Packaging Types, Features, and Applications

Various types of food packaging are available. Typical food packaging types, features, and applications are as follows.

- Pillow packaging

- In pillow packaging, the film is shaped into a tube, sealed, and then the base is welded to cut the package free. An inert gas such as nitrogen, carbon dioxide, or a mixture of these gases is then enclosed in the package.

- Application: Snack food

- Vacuum packaging

- The package is sealed with its interior close to a vacuum state, preventing oxidation and the generation of aerobic bacteria.

- Applications: Ham, bacon, and sausages

- Deep-draw packaging

- The bottom material is thermal shaped into the container, the contents are inserted, and then the air within the container is removed via the process that thermocompresses the top material, resulting in a vacuum seal.

- Applications: Ham, bacon, and sausages

- Skin packaging

- This is a type of vacuum packaging in which a film is placed on top of the contents and a piece of backing paper, and then the film is heated to form a gapless seal. This hermetic seal prevents drippage from the food, allowing for later expiration dates.

- Applications: Meat and dried food

- Top seal packaging

- Film is used as the lid to the container. Applying heat to the top seal pressure bonds it to the container.

- Applications: Jello, pudding, and tofu

- Shrink wrapping

- Thermal contracting film is used to package products with a tight seal that matches the product shape.

- Applications: Frozen pizza, multipack yogurt, instant noodles sold in a cup, alcohol sold in a box

Observation and Measurement Examples of Food Containers and Packaging Using a Digital Microscope

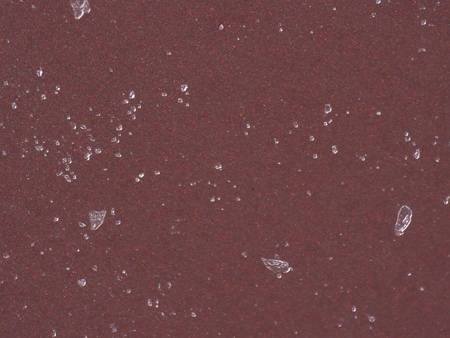

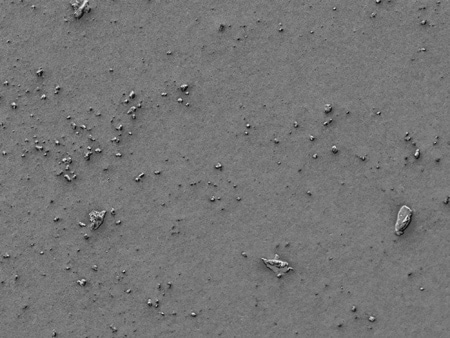

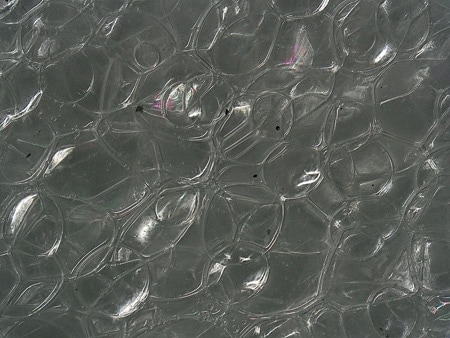

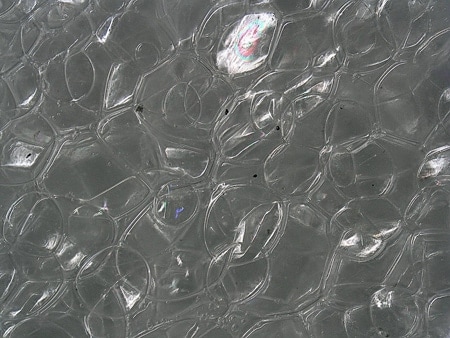

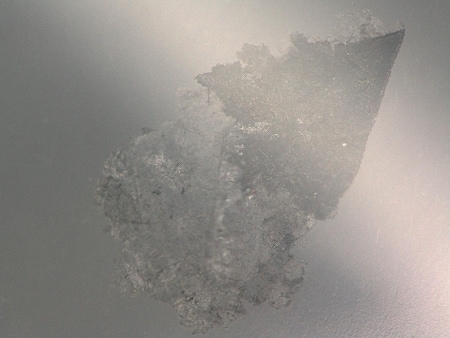

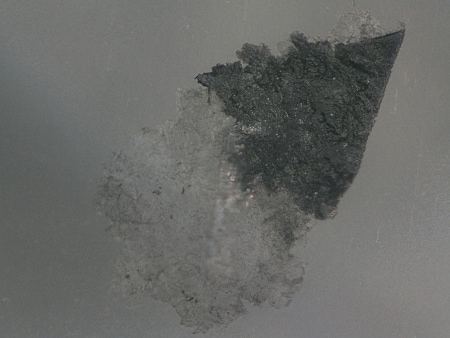

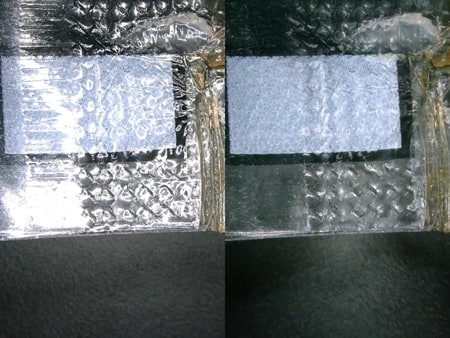

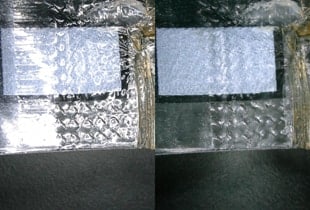

These are the latest examples of observation and measurement of food containers and packaging using KEYENCE’s VHX Series 4K Digital Microscope.