Inverted Microscopes

- What is an inverted microscope?

- Structure of inverted microscopes

- Inverted microscope applications

- Reasons for using a VHX Series digital microscope

What is an inverted microscope?

An inverted microscope is a microscope with the objective lens placed below the stage on which the sample is located, allowing the sample to be observed from below.

This type of microscope is used for observation at higher magnifications than stereoscopic microscopes, with magnification ranging from about 20 to 1500x.

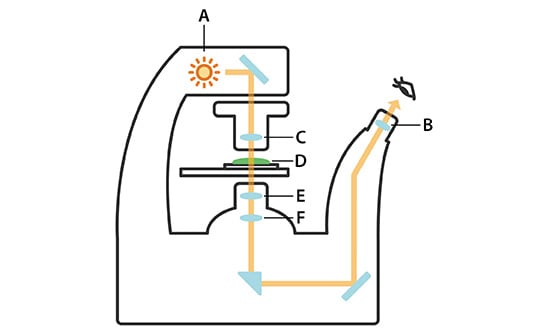

Structure of inverted microscopes

Inverted microscopes utilise an oblique light path leading to the eyepiece, allowing for observation in the same posture as a conventional microscope.

Because of the longer optical path, inverted microscopes use an optical system that relays the primary image from the objective lens to the eyepiece.

- A

- Light source

- B

- Condenser lens

- C

- Phase-contrast lens

- D

- Observation sample

- E

- Objective lens

- F

- Imaging lens

Inverted microscope applications

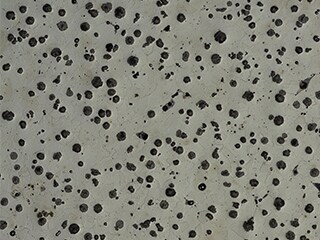

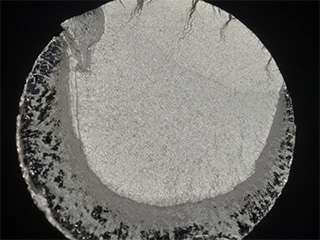

Inverted microscopes are commonly used in the medical and biological fields, which require observation of cells in culture vessels (Petri dishes) from below.

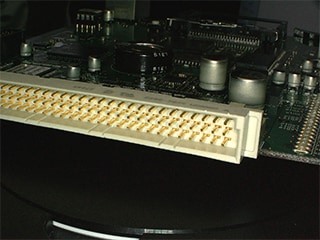

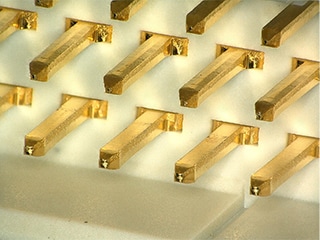

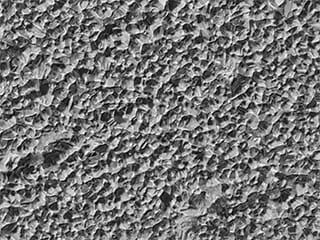

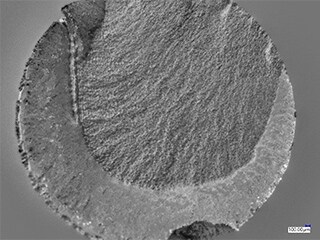

In industrial fields, inverted microscopes are used to observe metallic materials, which can be easily fixed and focused on simply by placing the material with a polished surface facing downward.

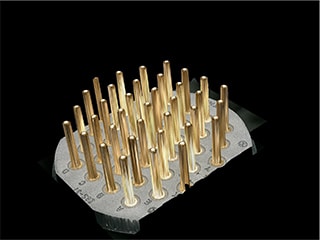

The lack of an objective lens above the stage also makes it possible to observe large, heavy samples.

Reasons for using a VHX Series digital microscope

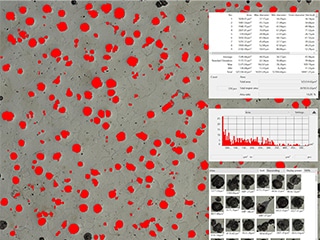

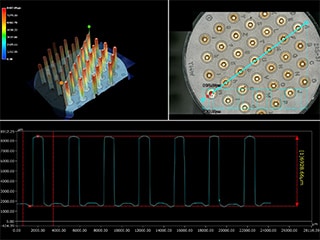

The long observation distance and large depth of field makes it possible to observe with the entire image on the screen in focus whether at low or high magnification.

This eliminates the need to cut or polish the target. (Non-destructive observation is possible.)

Optical Shadow Effect mode and the 4K camera allow for high-resolution imaging.

The standard-equipped measuring microscope functions allow for measurement of planes and 3D profiles.