Measuring Static Electricity

Before taking any static elimination measures, it is necessary to determine whether static electricity is actually present. The starting point is detecting static electricity. However, static electricity is not visible.

If there is a place with a visible problem, such as adhesion of a sheet or dust, you can tell that there is static. Using a dedicated measuring instrument can help you find static in places where there are no visible problems. A measuring instrument also allows you to see how strong the static is in a certain location.

First, let’s look at measuring instruments.

- What is an electrostatic sensor?

- Types of electrostatic sensors

- Amount and unit of static electricity

- Measuring method with reduced distance dependency

- Other measurement methods

What is an electrostatic sensor?

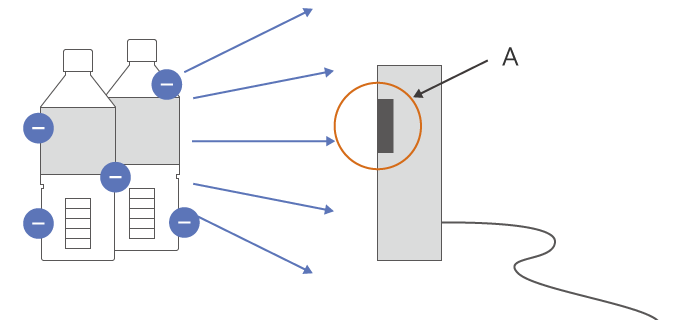

Electrostatic sensors are measuring instruments designed to detect static electricity. You can simply point the electrostatic sensor at the target to measure the amount of static electricity.

- A: The target is measured by simply pointing the sensor unit at it.

Types of electrostatic sensors

Instruments used to measure static electricity are officially called surface potential sensors or electrostatic field meters.

The figure below shows some examples. The example on the left shows measurement of static electricity on a PCB. The amount of static electricity can be easily measured just by pointing the sensor at the PCB.

Static electricity measurement at manufacturing sites may have different requirements: measuring multiple spots in a production line, measuring a certain location continuously and recording it, etc. Electrostatic sensors also come in various types for different applications, so it is important to select the appropriate sensor for the purpose and conditions.

- Hand-held-type Electrostatic Sensor

-

Portable-type for measuring any location

- Inline electrostatic sensor

-

Inline measurement

Amount and unit of static electricity

What is unit used to express the amount of static electricity? The unit is voltage. The amount of static electricity is indicated by how big or small the voltage number is.

Suppose you measured something using an electrostatic sensor. Product A had a voltage of 100 V. Product B had a voltage of 500 V. In this case, product B, which has a higher voltage, has more static electricity and stores more static charges. The higher the voltage, the stronger the charge. The smaller the voltage, the smaller the charge.

- A: An electrostatic sensor indicates voltage as shown here, which is the amount of static electricity.

Precautions for using a surface potential meter

There are two points that need to be noted regarding technique and measurement environment when using a surface potential meter.

- Precautions for measurement

- Differences in measuring distance and measurement target size between the time of initial adjustment and actual measurement, will impact the measured values.

-

- Distance dependency

The number of lines of electric force that reach the measuring instrument changes with the distance to the measurement target. Therefore, the measurement value will decrease if the measuring distance increases at the time of actual measurement compared to the reference distance during adjustment, and vice versa. - Target size-dependent measurement

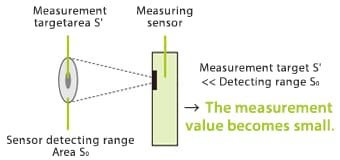

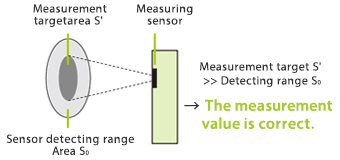

Many measuring instruments convert measurements with an assumption that the measurement target is infinitely large. If the measurement target is sufficiently larger than the measuring range of the measuring sensor, the correct measurement value is displayed. However, if the target is smaller than the detecting range, a smaller measurement value will be displayed. (Figure 5)

Figure 5: Target-size-dependent measurement - Distance dependency

- Precautions for measurement environment

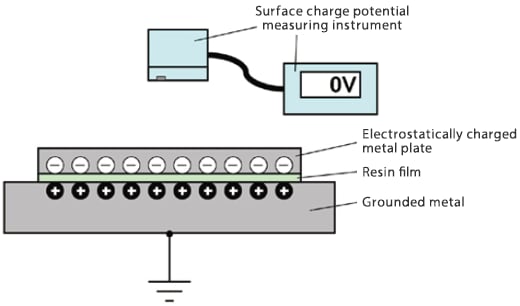

- What you need to be aware of when measuring the surface potential of a film attached to a metal plate or metal plates with a film in between is that even when these are charged, the potential will still be close to 0 V. Figure 6 shows an example of metal plates with a resin film in between. While the metal plate is charged, inductive charge appears on the grounded metal side, making it look like it is not charged by counteracting it. For this reason, caution is required when the measured target is in contact with grounded metal.

Figure 6: Example of metal plates with resin film in between

Measuring method with reduced distance dependency

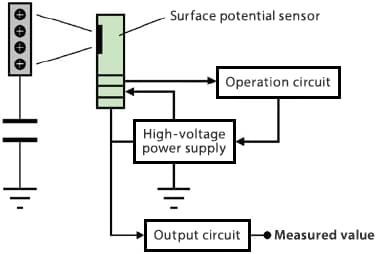

Surface potential meter with voltage feedback control

A surface potential meter detects the electric field strength instead of the potential, so it has distance dependency. A surface potential meter with voltage feedback control gives potential to the surface potential meter like ordinary surface potential meters but adjusts the output voltage of high-voltage power supply so that the sensor output is zeroed, which means that the electric field strength detected by the surface potential sensor is zero. The electric field strength detected by the surface potential sensor is zero when the voltage of the measured target and the sensor voltage are the same. In other words, the output voltage of the high-voltage power supply is the voltage of the measured target. Figure 8 shows a configuration example of a surface potential meter with voltage feedback control.

A surface potential meter with voltage feedback control has the advantage of reduced distance dependency, but its measurable voltage range is restricted to the range of voltage that can be output by the high-voltage power supply.

However, there are also types that control the output voltage of the high-voltage power supply and measure the surface potential of the measured target based on the output voltage and the surface potential meter’s output value. The measurable voltage range of these types is not restricted by the output voltage range of the high-voltage power supply, which allows for measurement over a wider voltage range.

Other measurement methods

Aside from using a surface potential measuring instrument as introduced earlier, there are three other ways to measure static electricity:

- Leaf electrometer

- Coulomb meter (current integration)

- Faraday cage method

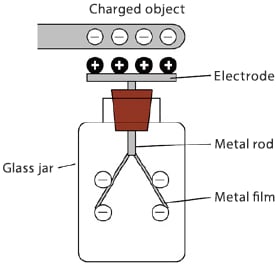

1. Leaf electrometer

You can check whether an object is electrically charged or not by putting a leaf electrometer close to the object.

Figure 1 shows an overview of a leaf electrometer. It has a metal electrode at the top and a metal rod connected to it inside a glass jar. There are metal leaves at the tip of the metal rod.

If you move a charged object close to the metal electrode, an electrical charge of a polarity opposite to that of the charge object is induced to the electrode due to electrostatic induction. A charge of the same polarity as that of the charged object appears on the metal leaf side. Since the leaves are charged with the same polarity, the leaves spread due to the repelling Coulomb force acting on the charges. The stronger the charge of the charged object is, the wider the leaves spread. The leaves close when the charged object is moved away, as there is no longer charge induction. Since this method requires no power supply, it is easy to use. However, it is affected by the direction of gravity, is not able to tell the polarity of charge on its own, and is not able to quantify the strength of the charge, so it is rarely used at product sites.

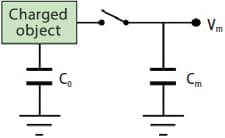

2. Coulomb meter (current integration)

A Coulomb meter measures the amount of electric charge by the probe touching the charged object. It works similar to a tester, but it can measure minute current (charge) that cannot be measured by normal testers. Figure 2 shows an overview of a Coulomb meter. To measure the amount of electric charge using a Coulomb meter, the charged object must be an object in which charge can move, like a conductor. Additionally, since a charged object loses charge via measurement, the measurement can only be performed once per sample. For these reasons, Coulomb meters are not commonly used. They are used when measuring the amount of electric charge on small devices, which are difficult to measure using a surface potential meter.

Vm is measured by moving the charge of the

charged object to capacitor Cm for measurement

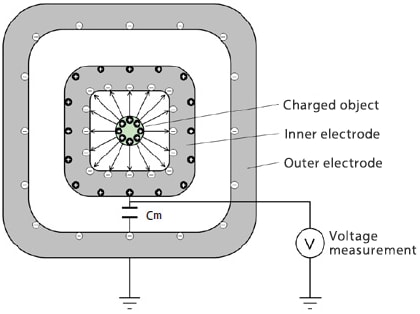

3. Faraday cage method

Similar to a Coulomb meter, the Faraday cage method measures the amount of electric charge on a charged object. It can measure the amount of electric charge without losing charge during measurement.

As the name implies, the Faraday cage method uses a container called a Faraday cage to measure the amount of charge.

Figure 3 shows the diagram of how the Faraday cage method works. You can see a completely insulated electrode in the inside and a grounded electrode on the outside. Placing a charged object inside the inner electrode causes charge to be induced to the inner electrode depending on the magnitude of charge on the charged object. The outer electrode is grounded. By measuring the potential difference Vm between the inner and outer electrodes, it obtains the amount of electric charge on the charged object.

While the Faraday cage method can accurately measure the charge on a charged object, it can only measure things that can fit inside the cage. In conclusion, surface potential meters are most commonly used at manufacturing sites for simple measurement purposes.