Electrostatic Discharge (ESD) Damage

Even small currents flowing through electronic parts such as integrated circuits (ICs) may cause circuit errors. Electrostatic discharge is no exception, and destruction of electronic parts by static electricity is called electrostatic discharge (ESD) damage.

This section explores how ESD damage occurs and how it can be dealt with.

How ESD damage occurs

ESD damage does not simply occur when a static charge is accumulated.

It occurs when accumulated electrostatic charge is discharged and causes a larger current than normal to flow in a circuit, generating heat that destroys the electronic part.

In other words, ESD damage does not occur without a discharge caused by static electricity. ESD damage can be prevented by creating a state where discharges do not occur.

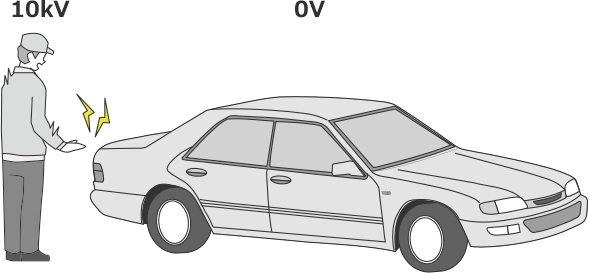

Whether or not there is a discharge depends on voltage (electric potential) differences. For example, if a person is charged with a voltage of 10 kV and a car is charged with a voltage of 0 V as shown in the following figure, touching the door results in a discharge. If there is a voltage (electric potential) difference between two objects, the discharge goes from the object with the high voltage to the object with the low voltage in an attempt to balance the voltages.

An environment free of discharges can be created by eliminating the voltage (electric potential) differences between electronic parts and the things that touch them.

Measures against ESD damage

There are three key points for preventing ESD damage:

- Do not generate static electricity (design-based measure).

- Eliminate static electricity (grounding, static eliminators, etc.).

- Prevent discharges (conductive mats, etc.).

The general static electricity management levels in various industries are listed below.

- Semiconductor industry: ±100 V or less (Resistance varies depending on the element)

- Liquid crystal industry: ±100 V or less

- MR head: ±10 V or less

- GMR head: ±5 V or less

The specific solutions to these problems are grounding, adding conductivity, and static eliminators (ionizers). Notably, static eliminators (ionizers) can be useful when grounding is unavailable.

Examples of measures taken for different causes

ESD damage to electronic parts can be classified into several patterns. Knowing how the damage occurs allows you to take effective measures.

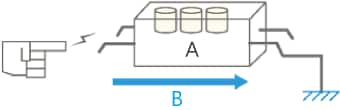

Human Body Model: discharge from human body to electronic part

- A: Device

- B: Current

A person charged with static electricity touches an electronic part, causing a discharge. In this case, part damage can be prevented by eliminating static from people via wrist straps and similar methods.

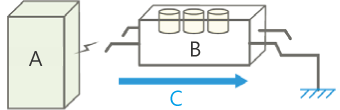

Machine Model: discharge from equipment to electronic part

- A: Equipment

- B: Device

- C: Current

A discharge occurs from an equipment charged with static electricity to an electronic part, damaging it. Grounding the equipment is an effective way to prevent these discharges.

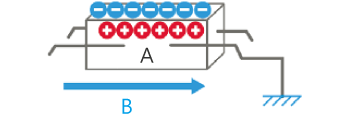

Charged Device Model: discharge caused by the charging of an electronic part

- A: Device

- B: Current

The electric charge accumulated within an electronic part is discharged elsewhere, causing damage. When there is a possibility of this occurring, the parts themselves must be neutralised and static eliminators (ionizers) are an effective tool.