High-Speed/Wide Area Static Eliminator

SJ-F300 series

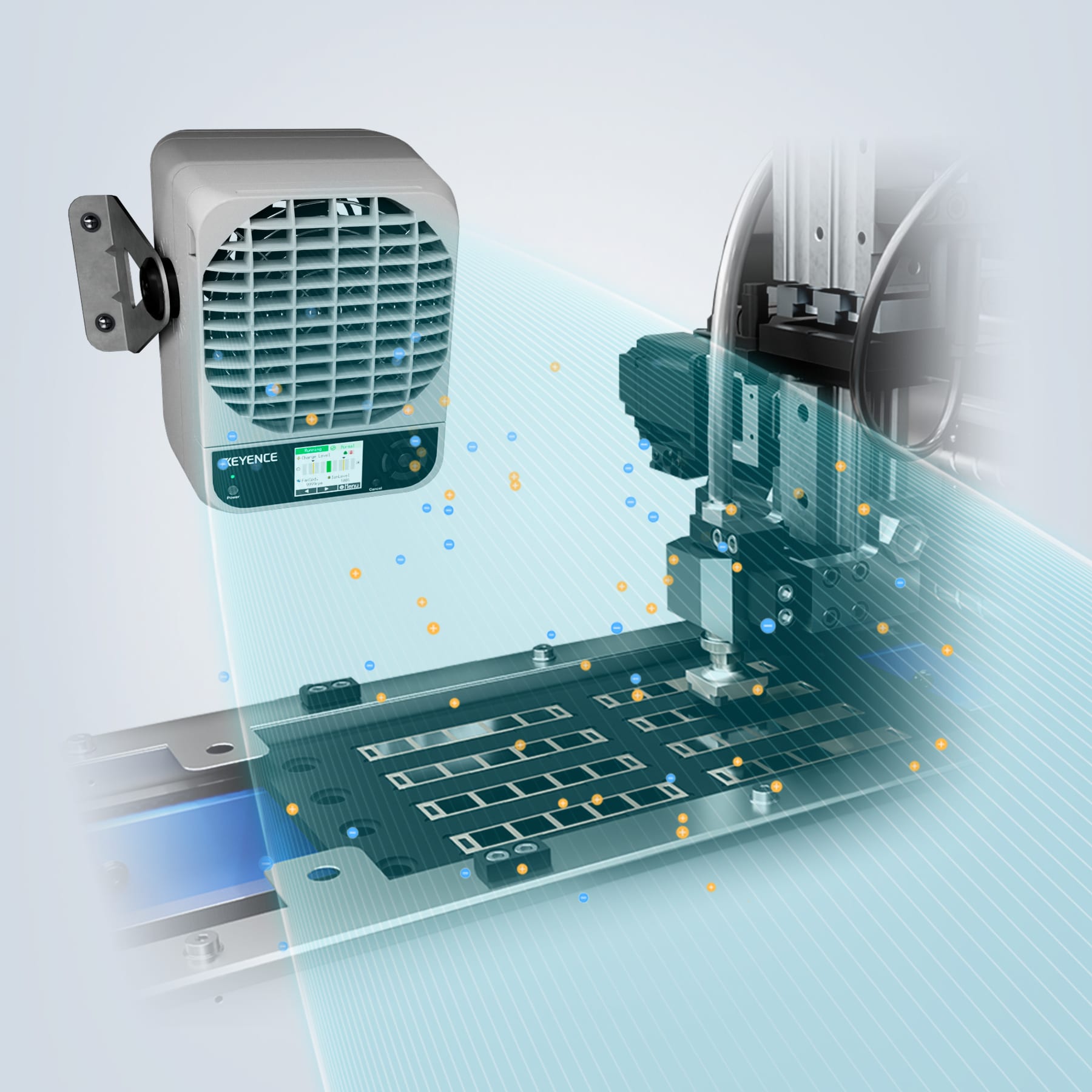

High-Speed/Wide Area Static Eliminator SJ-F300 series

Eliminate static electricity for a target area of up to 400 mm at an installation distance of 200 to 1000 mm. Without the need for an air supply, the SJ-F300 is suitable ...for desktop use.

RECOMMENDED

Latest Technology

Maintenance-Free, Reliable Static Elimination

- Maintenance free

- High-performance static elimination

- Ionizer traceability