Profile Projectors / Shadowgraphs

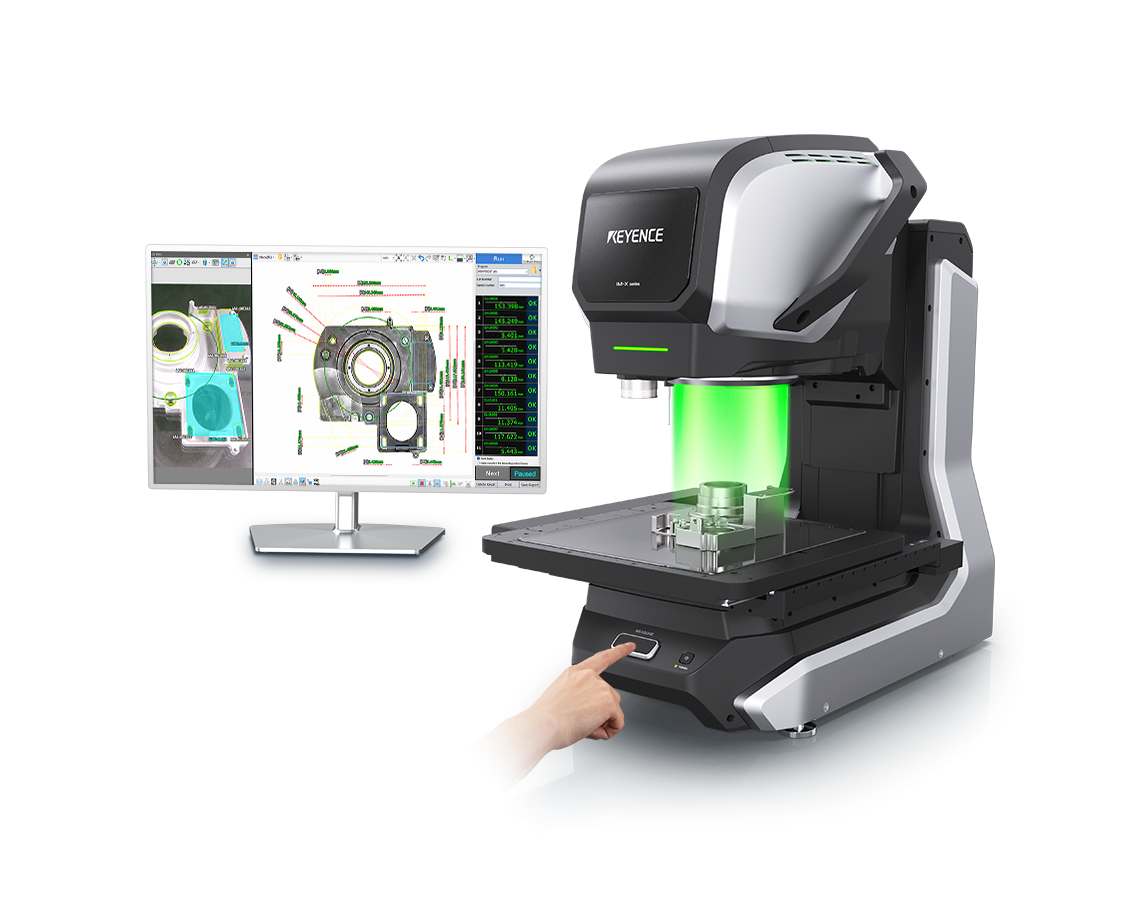

An automated, instant measurement system that provides highly accurate and repeatable measurement data in seconds; simply place a part on the stage and push one button! Hundreds of critical features can be dimensioned on the part anywhere within the system's field of view. Built in automatic edge detection software allows for measurements to remain consistent among all operators and eliminate subjectivity. This user friendly tool can be used by anyone to compliment your quality control processes whether it is being used in a lab or out on the shop floor.

Products Lineup

Instantly measure your parts with the push of a button. The Instant Measurement System takes place-and-press measurement to the next level with a significantly increased measurement range of up to 500 mm and multisensor capabilities including; optical, probe, laser, and rotary. This system features a new automatic drawing import function to help automate programming by importing CAD files and now PDF, JPEG and paper drawings. Furthermore, the built-in Smart Assist tool auto-optimises focus and lighting for expert level programming and optimal performance even with no prior optical metrology experience. This new Instant Measurement System enables fast, easy, and accurate inspections, even on large parts.

Features

For a Wide Range of Applications, From Small Parts to Large

New Feature: Extra-Wide Large Stage (500 mm in Size)

The system has a significantly increased measurement range that is 3.3x that of previous generations. Furthermore, it can handle taller parts with a maximum height of 2.7x that of previous generations. This latest system makes it possible to measure large parts with a single operation.

- Extra-wide large stage with dimensions of X: 500 mm × Y: 400 mm

- Increased Z range up to 200 mm

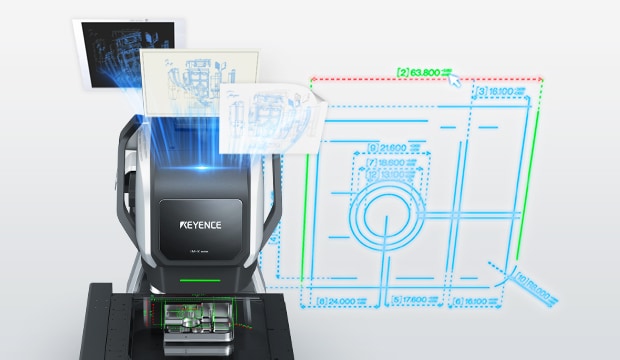

Import Drawings and Automatically Create Programs

From Drawing to Program in 3 Steps

Easily create programs by importing CAD, PDF, JPEG and even paper drawings. Just select your critical dimensions, design values, and tolerances to create a program.

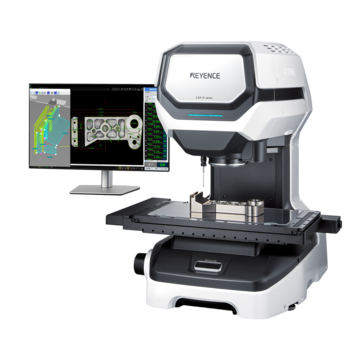

Capable of high-definition imaging, the IM-8000 Series Image Dimension Measurement System has triple the detection performance of conventional systems without sacrificing its simple operation; just place the part on the stage and press one button. With a 20-megapixel CMOS sensor and a new algorithm for stable edge detection, high-accuracy measurement on up to 300 features within seconds is now possible. A newly developed, optional automated rotary fixture allows for 360' multi-surface measurement on diverse part sizes and shapes. Achieve accurate and repeatable measurements instantly with its 'place and press' operation; this ensures consistent results regardless of operator experience. The fast, accurate, and easy-to-use interface of this product solve various measurement-related problems.

High-accuracy (±0.1 µm) measurement can be performed easily just by placing the part on the stage and pressing a button. Three measurement methods are available: high-accuracy image measurement, non-contact height measurement via a multi-colour laser, and contact measurement via a 3D touch probe. This product drastically reduces the dimensional measurement time of complex parts and ensures accurate measurements with no variations between results obtained by different operators.

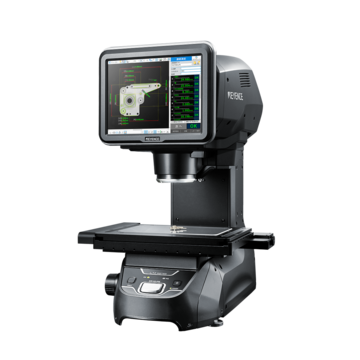

The LM Series High-Accuracy Instant Measurement System is an automated inspection system that can perform measurements to +/- 0.7 µm accuracy and +/- 0.1 µm repeatability at the push of a button. Similar to the IM Series, the unit has built-in edge detection with automatic focus and lighting. The unit also automatically records measurement data and creates detailed inspection reports. The image showcases our latest LM-1100 model which houses high-resolution double telecentric lenses for precision optical inspection and a large 9 x 5 inch field of view.